- Home

- What are Magnets?

- Products

-

Disc Magnets

Disc Magnets

-

Rod Magnets

Rod Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Sphere Magnets

Sphere Magnets

-

Cone Magnets

Cone Magnets

-

Countersunk Magnets

Countersunk Magnets

-

Custom Magnets

Custom Magnets

-

Hook Magnets

Hook Magnets

-

Eyelet Magnets

Eyelet Magnets

-

POT Magnets

POT Magnets

-

Rubber Coated Pot

Rubber Coated Pot

-

Disc Magnets

Disc Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Custom Magnets

Custom Magnets

-

Disc Magnets

Disc Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Custom Magnets

Custom Magnets

-

Disc Magnets

Disc Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Custom Magnets

Custom Magnets

-

- Applications

- Product Design

- Technical Support

2004

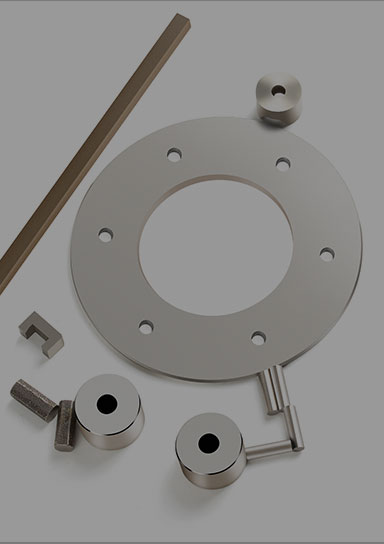

Product Forms of Magnets

Magnets come in various forms, from raw magnetic materials to finished products. Generally, magnetic materials undergo processing to create intermediate forms, which are then shaped into final products. This two-step process constitutes the typical manufacturing journey of magnetic products.

Raw Magnetic Materials

Raw magnetic alloys and powders

These are the basic materials used to create magnets, such as rare earth alloys, ferrite powders, or other magnetic compounds. They serve as the starting point for magnet production.

Intermediate Forms

- Sintered blocks

- Cast ingots

- Injection molded shapes

- Bonded magnetic sheets

- Extruded magnetic profiles

Intermediate forms are created from raw magnetic materials and can be broadly classified as:

(1) Forms made solely from magnetic materials, such as sintered blocks or cast ingots.

(2) Composite forms, which combine magnetic materials with binders or other materials, like bonded magnetic sheets or injection molded shapes.

These intermediate forms are developed to suit various applications and manufacturing methods.

Finished Magnetic Products

- Permanent magnets (various shapes)

- Flexible magnetic strips

- Magnetic assemblies

- Magnetic components for motors

- Magnetic sensors

These are products using raw magnetic materials or intermediate forms shaped into their final configuration. For example, permanent magnets can be cut and ground from sintered blocks, while flexible magnetic strips are often made from bonded magnetic sheets.

The most suitable intermediate form and manufacturing method are selected based on the shape and magnetic properties required for the final application.

Magnets and magnetic materials are versatile and can be tailored to meet specific needs across various industries, from consumer electronics to industrial applications and renewable energy systems.