- Home

- What are Magnets?

- Products

-

Disc Magnets

Disc Magnets

-

Rod Magnets

Rod Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Sphere Magnets

Sphere Magnets

-

Cone Magnets

Cone Magnets

-

Countersunk Magnets

Countersunk Magnets

-

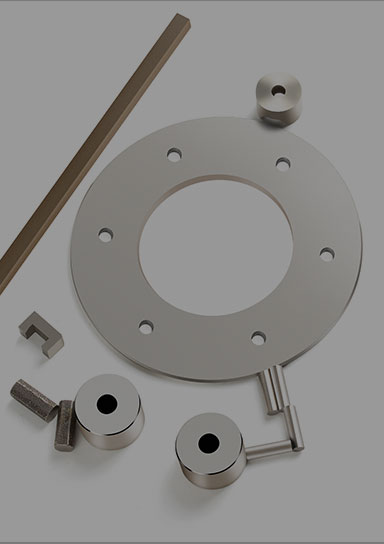

Custom Magnets

Custom Magnets

-

Hook Magnets

Hook Magnets

-

Eyelet Magnets

Eyelet Magnets

-

POT Magnets

POT Magnets

-

Rubber Coated Pot

Rubber Coated Pot

-

Disc Magnets

Disc Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Custom Magnets

Custom Magnets

-

Disc Magnets

Disc Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Custom Magnets

Custom Magnets

-

Disc Magnets

Disc Magnets

-

Block Magnets

Block Magnets

-

Ring Magnets

Ring Magnets

-

Arc Magnets

Arc Magnets

-

Custom Magnets

Custom Magnets

-

- Applications

- Product Design

- Technical Support

2004

Magnetization Methods for Magnets and Magnetic Materials

Magnets typically require magnetization to achieve their full magnetic properties. There are various magnetization methods, depending on the type of magnetic material, desired magnetic properties, and the shape of the final product. Here, we introduce typical magnetization methods for magnetic materials.

Pulse Magnetization

Pulse Magnetization

This method uses a brief, intense magnetic field to magnetize materials. It's suitable for hard magnetic materials like neodymium magnets and ferrites. The process is quick and can be used for high-volume production.

Continuous Field Magnetization

Continuous Field Magnetization

In this method, the magnetic material is exposed to a constant magnetic field for a longer duration. It's often used for larger magnets or when precise control of magnetic properties is required.

Thermomagnetic Treatment

Thermomagnetic Treatment

This process involves heating the magnetic material to a specific temperature while applying a magnetic field, then cooling it in the presence of the field. It's particularly useful for creating anisotropic magnets with enhanced magnetic properties in specific directions.

Multi-Pole Magnetization

Multi-Pole Magnetization

This method creates multiple magnetic poles on a single piece of magnetic material. It's commonly used for motor magnets, sensors, and other applications requiring complex magnetic field patterns.

Oriented Field Magnetization

Oriented Field Magnetization

In this process, the magnetic field is applied in a specific direction during the material's solidification or sintering process. This creates magnets with strong magnetic properties along a preferred axis.

Impulse Magnetization

Impulse Magnetization

Similar to pulse magnetization, but using even shorter duration, higher intensity magnetic fields. It's useful for magnetizing materials with very high coercivity.

Capacitor Discharge Magnetization

Capacitor Discharge Magnetization

This method uses the discharge of a large capacitor bank to create a brief, extremely strong magnetic field. It's effective for magnetizing the hardest magnetic materials.

Electromagnet Magnetization

Electromagnet Magnetization

This method uses powerful electromagnets to create the magnetizing field. It offers flexibility in field strength and duration and is suitable for a wide range of magnetic materials.