Bonded & Injection Magnets: Powering the Future

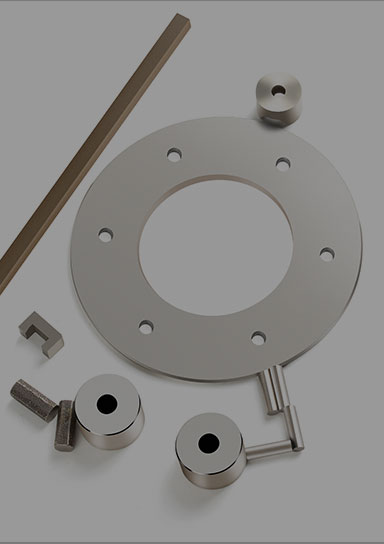

Bonded Neodymium magnets are manufactured through the compression process. This process involves mixing neodymium powder with epoxy as a binder and pressing it into a die cavity with no magnetic field, thus making these magnets Isotropic. Pressed parts are then placed into the oven for curing. Compression bonded neodymium magnets are an excellent choice over other magnet types (sintered neodymium, sintered samarium cobalt, and hard ferrite magnets ) that have limits to some shapes that compression bonded magnets do not have. With their high energy product reaching up to 12 MGOe it makes them ideal for many applications requiring high magnetic strength and tight tolerances. Since no magnetic field is applied during the compression the finished product can be magnetized in any direction. Having epoxy as a binder in the manufacturing process for compression bonded magnets makes the magnets resistant to most industrial automotive fluids. With relative low tooling cost and quick turnaround compression bonded neodymium magnets are the choice for a wide variety of applications. The final product can be epoxy coated for durability and more resistant to corrosion